Turning with MPCNC and lost foam aluminum casting

Making of an axisymmetric model with a three axis CNC and lost foam aluminum casting.

Turning with MPCNC and lost foam aluminum casting - Mazzo.me

Turning with MPCNC and lost foam aluminum casting - Mazzo.me

Video of the turning of an axisymmetric foam model with my three axis MPCNC to make an aluminum knob with lost foam casting:

The tool used was fixed:

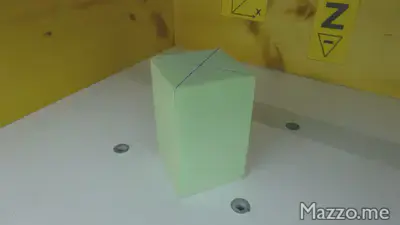

The initial piece was a parallelepiped foam:

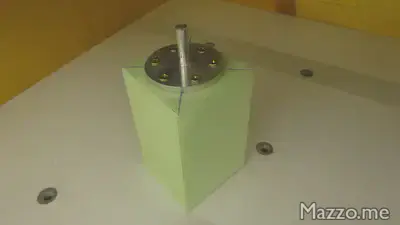

I made a tool to take the foam in the spindle:

After the turning the piece had to be finished:

I finished it with sand paper:

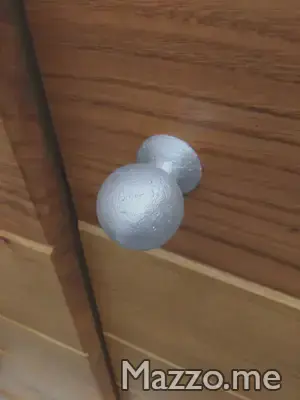

And I covered it with quartz paint:

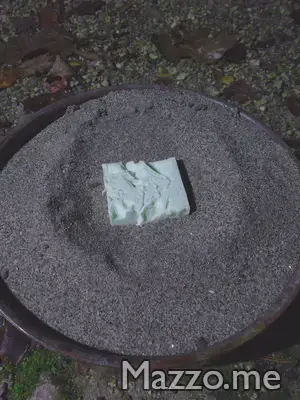

The model was inserted in the sand to do the casting:

The aluminum was melted with an electric oven:

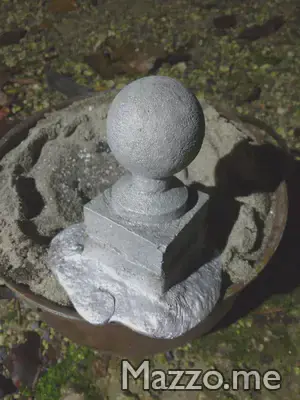

And a raw piece was obtained from the casting:

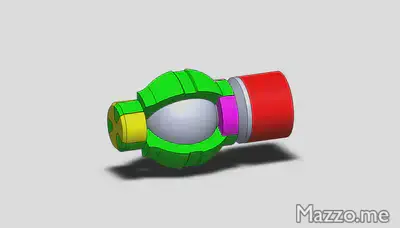

To finish the obtained piece on the lathe, I made some supports with my 3D Printer:

Turning the mounting face:

And threading the hole to mount the knob: